How TetraPhos® works

Search

REMONDIS Aqua Company locations

The whole picture – with just a single click. Find out here where our branches are located, what services they offer and how to contact them.

REMONDIS Group locations

Discover the world of REMONDIS with its 1,000+ branches and associated companies in more than 30 countries across Europe, Africa, Asia and Australia.

There’s no getting around phosphorus recovery.

Thank goodness

Recovering phosphorus is the future. All large sewage treatment plants in Germany will be obliged, by law, to recover the phosphate from their municipal sewage sludge from 2029 onwards. And all the signs are pointing towards other European countries following suit. Having said that though, it would be wrong to consider the subject of phosphorus recovery merely from the point of view of whether it meets statutory requirements or not. Almost all of the world’s phosphorus reserves are outside Europe making it a very scarce raw material. Recovering phosphorus so that it can be reused is simply something that makes sense – both economically and environmentally. That is especially true when it involves sewage sludge, which is such a rich source of raw materials. The amount of sewage sludge produced in Germany alone contains around 60,000 tonnes of phosphorus.

Phosphorus recovery – who to contact:

Andreas Rak

Gregor Timmerhaus

Phosphorus recovery – the film

Phosphorus is a vital raw material in every sense of the word. Nothing on our planet can grow or exist without it.

Why local authorities should count on

REMONDIS Aqua to recover their phosphorus

We realised very early on just how much potential sewage sludge has to be a source of raw materials and a means to help curb climate change. We developed TetraPhos® – our patented phosphorus recovery process – many years ago, making us a pioneer in this field. Sewage sludge ash, the residual material from thermal sewage sludge utilisation, is used to produce high-purity phosphoric acid, which can be used to produce fertiliser for agriculture, for example. This acid can also be used for many other industrial applications, for example for protecting against corrosion. Thanks to our know-how and experience in this area, you can rest assured that you will be able to successfully recover phosphorus as part of your municipal wastewater treatment system. And not sometime in the future but right now. As a general rule, the earlier this subject is tackled, the better.

The benefits of having your own TetraPhos® facility

Improved carbon footprint

Several product life cycles are closed and high quality recycled raw materials produced. What’s more, the REPACID ® production process cuts carbon emissions by 60% compared to imported phosphoric acid – giving it an excellent environmental footprint.

Nutrients & pollutants safely separated

The phosphoric acid is a standard and fully marketable recycled raw material that can be used for a wide range of applications – there are no restrictions.

Legally compliant

Way over 80% of the phosphorus is recovered from the sewage sludge which more than satisfies the targets set out in the amendment of the German Federal Sewage Sludge Ordinance [AbfKlärV] – making it a future-proof system.

Cost-effective

The phosphoric acid obtained and the by-products generate revenues that contribute to profitability.

If all the volumes of sewage sludge produced in Germany each year were sent to phosphorus recovery facilities, this would have the same effect on reducing CO2 levels as around 27 million trees.

Getting the right advice about recovering phosphorus from the start

More and more local authorities and water associations are deciding to invest in mono-combustion plants for treating their sewage sludge as they are well aware that it will soon be mandatory for them to recover phosphorus and that there are not enough suitable recycling capacities available. REMONDIS Aqua is just the right company to discuss these projects with and, if you wish, to implement them on your behalf. At the end of the day, anyone planning to build a plant to thermally treat sewage sludge must automatically also be thinking about having a future-proof system – i.e. one that includes phosphorus recovery – considering the long time needed to realise such projects. We can help you to draw up a concept and build your incineration plant so that your sewage sludge ash is recycled in the best possible way and your plant has the right general set-up for recovering phosphorus. For example, by having the plant produce steam that can then be used for the phosphorus recovery process.

From 2023 onwards, operators of large sewage treatment plants must present a concept showing how they intend to recover their phosphorus. This decision was set out in law in October 2017.

We’re more than happy to meet you to discuss how we can help you to recover your phosphorus. Simply get in touch with us

Getting the very most out of sewage sludge

Our TetraPhos® technology turns sewage treatment plants into urban mines and a source of raw materials. We make the very most of the fact that the ash left over after the sewage sludge has been incinerated still contains a large amount of recyclable substances. Including phosphorus. We recover this by using the thermal pre-treatment stage and a physical-chemical process. We use the sewage sludge to generate energy and then mix the sewage sludge ash with phosphoric acid so that the acid is enriched with the phosphate in the ash. The result is an ultra-pure phosphoric acid called REPACID®. The biggest advantage of this brand-name recycled product: it is not only of a higher quality than acid made from virgin raw material (as this is often contaminated with heavy metals) but is also much better for our climate. Its environmental footprint is considerably better than that of imported phosphorus.

The TetraPhos® process was presented with the GreenTec Award back in 2016.

For smartphones and tablets:

Discover TetraPhos® as a virtual 3D experience.

Immerse yourself in the world of phosphorus recovery with our app and downloadable graphic.

Three simple steps:

1. Download the app for iOS or Android.

2. Download and open the PDF with the graphic of the plant

3. Start the app and scan the points on the graphic

Phosphorus – a vital and much-sought-after substance

If you’re asking yourself why the spotlight is being turned on phosphorus recovery and why international and national legislation is driving this subject forward, then you simply need to take a look at the world’s phosphorus resources. Practically all deposits of phosphate rock are found beyond the European continent and are mined in regions that sometimes have a politically complex landscape. For example in Morocco, China, Jordan, Russia and South Africa. Which means that Europe is highly dependent on imports of a raw material that is essential for all life on our planet and that is in danger of becoming more and more scarce as the world’s population increases. Studies – including studies from the German Environmental Agency (UBA) – forecast that there will be a worldwide shortage of phosphorus from 2070 onwards. Reason enough, therefore, to recover and recycle every single gram of this precious raw material and take a step further towards becoming less dependent on the global market.

Phosphorus recovery – and transitioning from virgin to recycled raw materials – is just one part of a package of climate action measures that REMONDIS is calling for. Find out more at

we-are-climate-action.com

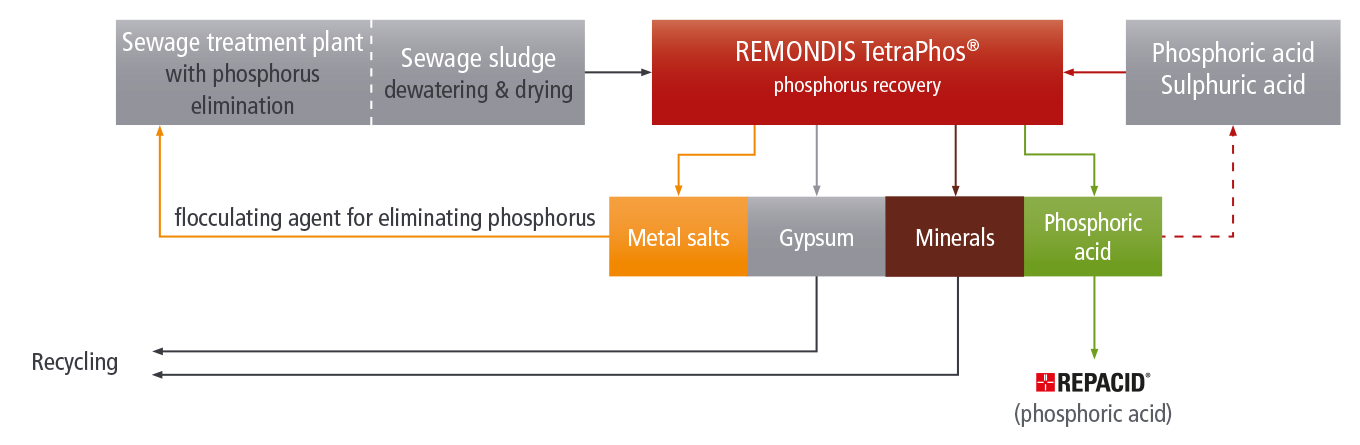

A cycle within a cycle

One of the reasons why the TetraPhos® process is particularly environmentally friendly is because it creates a self-sustaining cycle. The iron and aluminium salts that are recovered from the sewage sludge ash alongside the phosphorus can be reused by the sewage treatment plants to eliminate phosphate. And, of course, some of the acid produced by the phosphorus recovery process remains in the cycle so that it can be reused to recover more phosphorus. What’s more, this system also generates recycled gypsum and minerals of a consistently high quality that can be marketed for a variety of applications. Both are used by the building supplies trade – helping to reduce demand for virgin raw materials in this sector, too.

Recycled phosphorus – better than its virgin counterpart

Reason 1: Higher quality

Imported phosphorus from mines is often contaminated with heavy metals and uranium. Whereas our recycled product REPACID® is extremely pure.

Reason 2: Lower dependency on imports

Recycled phosphorus acts as a safeguard against raw material shortages and the vagaries of the sometimes volatile and politically unstable markets.

Reason 3: Climate action

Production-related carbon emissions are reduced by ca. 60% as recycled phosphorus is produced on site close to where it is needed.

Sewage sludge on our fields? That’ll soon be a thing of the past

A further argument for using TetraPhos® to recover phosphorus is that the direct application of sewage sludge on agricultural land is gradually being phased out. While many countries still allow sewage sludge to be spread on fields if certain ceiling values are complied with, there is a clear trend towards sewage sludge and slurry no longer being permitted to be used as fertiliser. This also explains why the regulations in Germany are getting steadily more stringent. Sewage treatment plants with over 100,000 population equivalents must recover their phosphorus from 2029 onwards and plants with over 50,000 population equivalents from 2032. Technically speaking, fertilising land with sewage sludge does count as a form of phosphorus recycling. It remains, though, a questionable solution as it can potentially have a negative impact on the environment. It is, without doubt, considerably more environmentally friendly and a more sustainable solution for farmers if phosphate fertiliser is produced from recycled raw materials rather than continuing to spread tonnes of – to a greater or lesser extent – contaminated sewage sludge on the fields. And, of course, recycled phosphorus can be used in a whole number of other areas. For example, to produce animal feed.

So are there phosphorus recovery systems for industry, too?

Phosphorus can also be found in industrial wastewater depending on which sector our customers operate in. Having said that though, industrial wastewater has two disadvantages compared to wastewater in municipal sewage treatment plants when it comes to recovering phosphorus: the composition of the industrial wastewater is considerably more heterogeneous across all customers and the volumes produced are much smaller. Both these factors mean that REMONDIS Aqua uses a different solution here. The name of this solution is REPHOS®. This is a process that we developed ourselves as part of our industrial wastewater treatment operations. This system enables phosphorus to be removed straight from the wastewater as magnesium-ammonium-phosphate (MAP).

You might also be interested in …

Research & Development

Many other technologies are available, such as smart sensor technology for sewers.

more

Municipal wastewater management

A whole range of services covering wastewater treatment – from delivering infrastructure services through to managing plant operations.

more

Services

We offer engineering services, analytical services and much, much more.

more